Dry Honeycomb Rapid Gas Cooling System

This system was developed as an exhaust gas cooling system for small sized incinerators under a grant from a subsidiary of the Osaka Prefecture Technology Improvement Promotion Fund for advanced technologies.

By adopting a ceramic honeycomb whose heat transfer area per unit volume is large, we could develop a dry cooling system that was smaller and of higher performance than conventional dry cooling systems.

Dioxins generated in waste incinerators can be decomposed once by high-temperature combustion in the furnaces. However, these dioxins re-synthesize when they pass the lower temperature region of approximately 300℃ in the process where the combustion gas is exhausted.

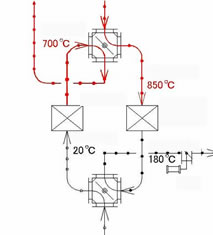

The dry honeycomb rapid gas cooling system cools high-temperature exhaust gases at 850℃ down to 200℃ or lower within a few seconds, which prevents drastically re-synthesis of dioxins.

The system cools exhaust gases rapidly while raising air temperature, which allows energy saving through effective use of the high-temperature air.

System flow diagram